Static electricity is not the most heavily researched area of science, as historically, unlike current electricity, which has been used in different ways to provide energy, it has not been considered useful.

In industry, it is still very often more a matter of judgement than of scientific knowledge. The complex physical and chemical properties of interacting objects and environments make it difficult to carry out any accurate analysis and there are problems measuring static electricity.

THE FOUR MAIN PROBLEMS RELATED

TO STATIC ELECTRICITY

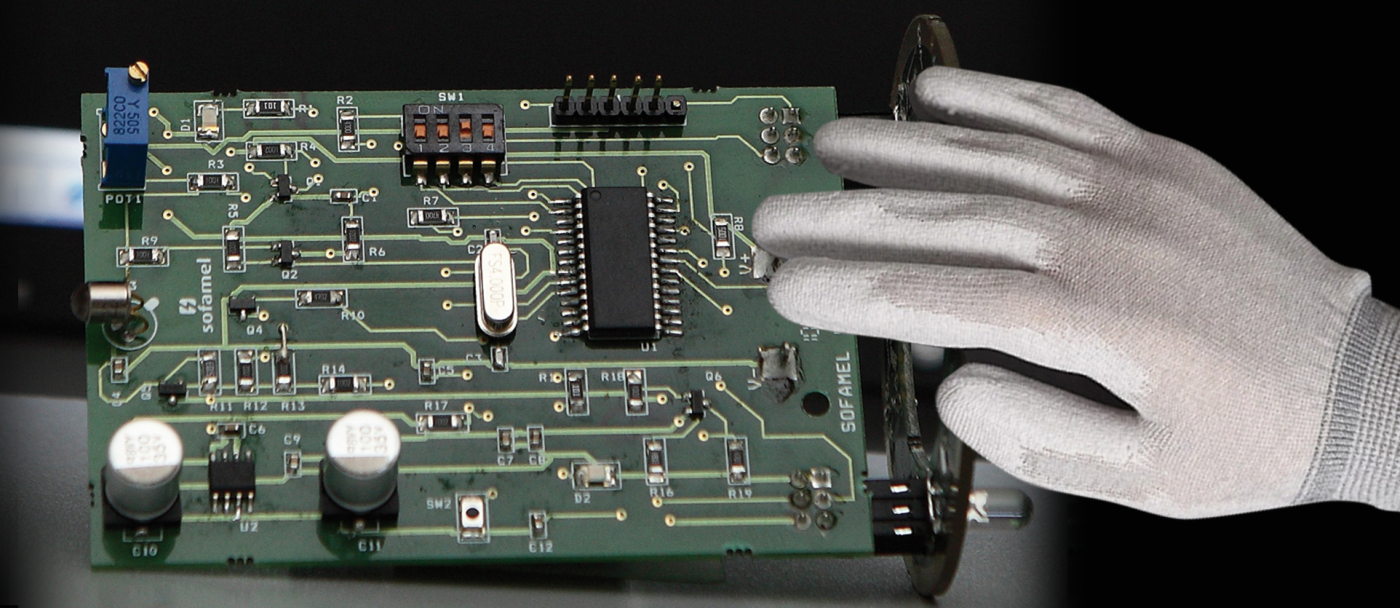

1. Static discharge in electronics

The main danger associated with static charge in electronics is from the person in contact with a component. An electronic discharge generates heat, which can burn connections, disrupt contacts or break microchips.

Often, components do not fail completely, which can be even more dangerous, as the fault does not manifest itself immediately, but unexpectedly during that operation of the device.

As a general rule, when working with static-sensitive parts and devices, measures should always be taken to neutralise the static charge accumulated on the body (anti-static gloves, ESD footwear, static dischargers).

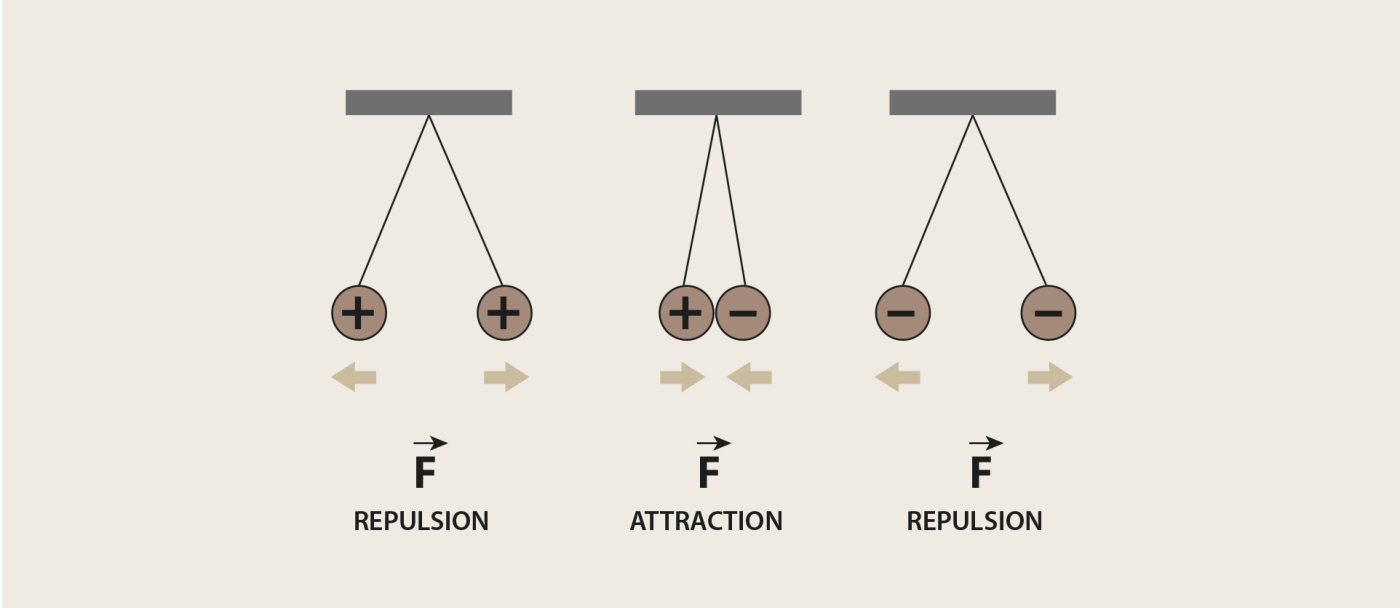

2. Electrostatic attraction/repulsion

This is perhaps the most widespread problem in plastic, paper and textile production and processing. The issue manifests itself in a change in the behaviour of the material: sticking or pulling away, sticking to equipment, attracting dust, incorrect winding, etc. The problem can be neutralised with static ionisers.

3. Fire risk

The risk of fire is not a problem that is common across all industries. However, there is a very high likelihood of fire in facilities where flammable solvents are used.

The most common sources of fire in hazardous areas are ungrounded equipment and moving conductors. If an operator in a hazardous area is wearing footwear with NON CONDUCTIVE (insulating) soles, there is a risk that a charge can be generated by their body, which could ignite the solvents. It is very important to understand that footwear in these environments must be conductive, antistatic or (ideally) ESD.

Conductive footwear is a type of work footwear that has a level of electrical resistance, which, while low, is high enough to allow electrostatic charges to dissipate, reducing the risk of build-up of these charges. This footwear has low electrical resistance, so its use is only recommended when the possibility of coming into contact with live materials has been completely eliminated.

In order to avoid the risks that affect conductive footwear, antistatic footwear is available: this has a higher electrical resistance than conductive footwear. Antistatic footwear can be defined as having a medium resistance and capacity to dissipate electric discharges caused by electrostatic charges. Footwear marked as ESD is regulated by EN 61340-4-3: 2005. This type of footwear is similar to that mentioned previously, but with extreme protection. ESD footwear is footwear with maximum electrostatic charge dissipation. There are professions, such as those that work with printed circuit boards or in clean rooms, where even the slightest static charge can cause a serious accident. ESD footwear has therefore been developed to conduct even the smallest electrostatic charges accumulated by the worker: this type of footwear is designed to divert these charges away from the user.

Anti-static gloves are another important way to prevent the build-up of high levels of static and allow it to dissipate to earth.

An ungrounded machine is another hazard. Everything in the hazard area must be properly grounded.

4. Electric shock

The risk of static shock in an industrial environment is increasingly more an issue, as it can cause serious accidents and is especially dangerous for people with heart problems.

The most common cause of static shock is induced charge, as can occur, for example, in the plastics industry.

If the operator is wearing shoes with insulating soles, the charge will remain on their body until they touch a grounded piece of equipment, when the charge will flow to the ground and injure the person. This can also occur when the operator touches charged objects or materials: insulating footwear causes the charge to accumulate on the body. When the operator touches a metal part of the equipment, they receive an electric shock.

Conclusion

In areas where static electricity is generated, it is essential to take the correct precautions according to each case.